Compressor Motor Starter: Everything You Need to Know

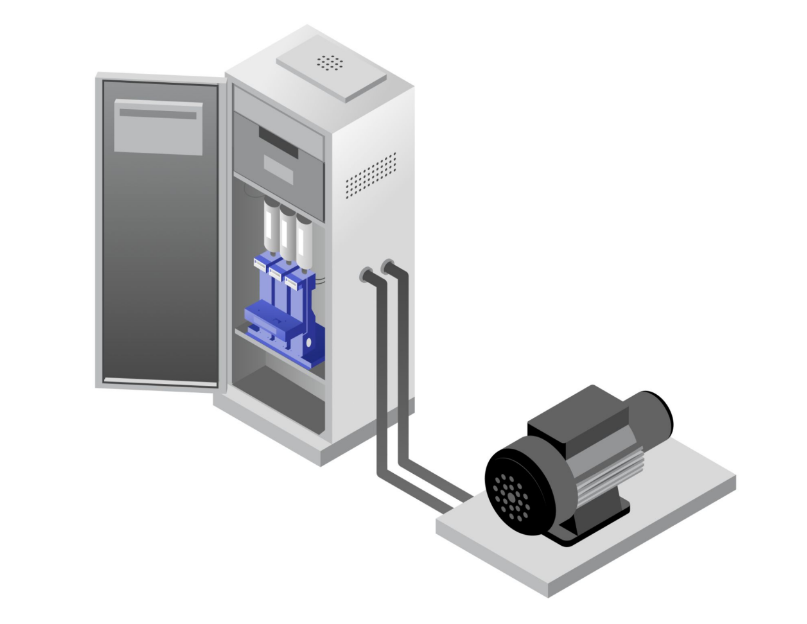

What is a Compressor Motor Starter?

The contactor is a switch that controls the flow of electrical power to the motor. When the start button is pressed, the contactor closes, allowing electricity to flow through the motor. When the stop button is pressed, the contactor opens, cutting off the flow of electricity to the motor.

The overload relay is a safety device that protects the motor from damage due to overload. If the motor draws too much current, the overload relay will trip, cutting off the flow of electricity to the motor. This prevents the motor from overheating and potentially causing damage..

Why are Compressor Motor Starters Important?

Compressor motor starters are important because they help to protect the motor from damage, prevent overload, and ensure efficient operation. They are designed to control the flow of electrical power to the motor, which helps to prevent the motor from drawing too much current and overheating. This can help to extend the life of the motor and prevent costly repairs.

In addition, compressor motor starters can help to improve the efficiency of the compressor system. By controlling the flow of electricity to the motor, the starter can help to reduce energy consumption and save money on electricity costs.

How do Compressor Motor Starters Work?

Compressor motor starters work by controlling the flow of electrical power to the motor. When the start button is pressed, the contactor closes, allowing electricity to flow through the motor. The motor then begins to spin, which creates a magnetic field that causes the contactor to remain closed.

Once the motor is up to speed, the overload relay monitors the current flowing through the motor. If the motor draws too much current, the overload relay will trip, cutting off the flow of electricity to the motor and preventing it from overheating.

When the stop button is pressed, the contactor opens, cutting off the flow of electricity to the motor and bringing it to a stop.

Compressor motor starters are an essential component of a compressor system that helps to protect the motor from damage, prevent overload, and ensure efficient operation. They work by controlling the flow of electrical power to the motor, and consist of several components including a contactor and an overload relay..

Frequently Asked Questions:

Q: What is the role of a compressor motor starter?

A: The compressor motor starter controls the power supply to the compressor motor and protects it from electrical damage. It ensures the smooth operation of the motor and extends its lifespan.

Q: What are the types of compressor motor starters?

A: There are three primary types of compressor motor starters: Direct On-Line Starters, Star-Delta Starters, and Soft Starters.

Q: What is the difference between DOL starters and soft starters?

A: DOL starters provide full voltage to the motor during startup, which can cause a high inrush of current. Soft starters provide a gradual increase in voltage to the motor during startup, which reduces the inrush current and mechanical stress. Soft starters also provide energy efficiency benefits.

A: Compressor motor starters protect the motor from electrical damage by monitoring the current flow, voltage, and phase sequence. They trip and disconnect the motor from the power supply if any of these parameters exceed the set limit.

Q: Can a compressor motor starter be repaired?

A: Yes, a compressor motor starter can be repaired if the damage is minor. However, if the damage is severe, it may be more cost-effective to replace the starter.

Q: How often should compressor motor starters be maintained?

A: Compressor motor starters should be maintained as per the manufacturer's recommendations. Generally, they should be inspected and tested annually to ensure their proper functioning.

Q: What are the signs of a faulty compressor motor starter?

A: Some signs of a faulty compressor motor starter include abnormal noise, irregular motor operation, frequent tripping of the circuit breaker, and burning smell.

Voltage: Up to 1.5kV | Amperage 200,400,600 max | <1A Chopping Current | Auxiliary Contacts | Opening Time 120ms | Closing Time 20-40ms Learn more »

Voltage: Up to 7.2kV | Amperage 1500 max | <1A Chopping Current | Auxiliary Contacts | Opening Time 90ms | Closing Time <40ms

Learn more »

Voltage: Up to 3.6kV | Amperage 600 max | <1A Chopping Current | Auxiliary Contacts | Opening Time 90ms | Closing Time 17ms Learn more »

Voltage: Up to 7.2kV | Amperage 600 max | <1A Chopping Current | Auxiliary Contacts | Opening Time 90ms | Closing Time 40ms Learn more »