What are Switching Transients and Why do They Occur?

Switching transients occur in power systems each time an abrupt circuit change occurs. This phenomena is attributed by the combination of two factors in motor applications: the mechanical energy stored in the rotating machine and the electrical energy stored in the inductive load. These transients are short lived and oscillatory in nature. However, they are extremely important as the electrical equipment is subjected to its greatest stresses during this period. When the two electrical contacts separate, an arc is created in the interrupter that maintains current flow. As the current approaches its next zero-crossing, the arc weakens then extinguishes. The sudden current chop induces voltage transients within the inductive load. It is critical to minimize the chop current level to reduce transient over-voltages which can damage insulation systems.

Featured Products

CV Series Compact Vacuum Contactor

Joslyn Clark’s Compact CV Series Vacuum Contactors and Starters are ideal for tough industrial applications. The compact design provides flexibility for retrofitting air break contactors, thus enabling an existing application to continue with maintenance cost and down time eliminated. Voltage raging from 600V to 1500KV and current ratings up to 600A are available.Learn more »

MVC Series Medium Voltage Vacuum Contactor

The Joslyn Clark USAVAC medium voltage vacuum contactors are 3-phase motor contactors built for control and protection in medium voltage applications ranging from 2300V to 7200V. Current ratings of 200-1200 ampere, and motor ratings up to 7000 HP at 6600V are available.Learn more »

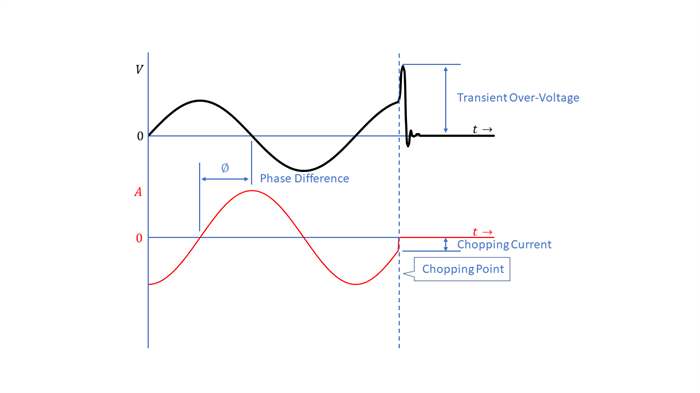

In a typical switching operation, such as a contactor or breaker opening or closing, switching transients occur on an electrical load each time an abrupt circuit change, or current chop, occurs. Inductive loads are most sensitive to such abrupt circuit changes. Below, Figure 1 illustrates that the current lags the voltage in an inductive load. The most severe transient over-voltage condition is observed prior to the current zero-crossing.

Current chop before current zero causes voltage spikes (known as switching transients) can damage loads like electric motors or dry type transformers. Over-voltages from switching transients may result in insulation degradation. Over time, this can lead to flashovers or insulation breakdown. Flashovers can trip protective devices and force equipment to be out of service. Eventually, insulation breakdowns leads to permanent equipment damage. A vacuum contactor’s low switching transient prolongs the life of inductive loads by minimizing chop current which, in turn, minimizes switching transients.

How Can You Minimize Switching Transients with Vacuum Contactors?

To minimize switching transients, or reduce transient over-voltages, the arc in the vacuum interrupter must maintain current flow to the load as close to the next current zero crossing as possible while the contacts are opening. The dielectric strength between the opening contacts must also increase to a point where it is strong enough to prevent a restrike after current chop.The selection of contact material impacts switching transient voltages. Below, Figure 2 compares the chop current level of three commonly used contact materials in vacuum interrupters. The proprietary WCAg contact material in Joslyn Clark Vacuum Contactors leads the industry with the lowest chop current level, therefore creating the lowest switching transient.

Figure 2. Comparison of chop current level across different contact materials used within vacuum interrupters.

Vacuum Contactor Advantages Over Circuit Breakers

The standard circuit breaker design couples high interrupting capability with infrequent switching of high currents, typically over 600 amps. To achieve a high level of interruption, the designer must use a hard contact material capable of handling extremely high temperatures. As the contacts open, the vacuum breaker interrupts the current as soon as possible. The abrupt cutoff of current, typically 3-5A in modern vacuum breakers, induces higher voltage transients that can damage inductive loads. Many published literature pieces by the IEEE address this particular issue with the addition of surge suppression or filter components.However, vacuum interrupters designed for use in a vacuum contactor do not require additional components. This benefit further reduces overall cost and system complexity. Vacuum contactors typically involve switching motor loads of less than 600A, with a 4-6KA interrupt level, and are switched very frequently. In motor switching applications, Joslyn Clark Vacuum Contactors are always the right solution over vacuum breakers or other contactors with inherent high current chop characteristics. With many contactor manufacturers claiming low current chop levels, their publications remain silent on what these levels are. Joslyn Clark has always published the current chop level of our vacuum contactor and expressed it as a maximum of 0.9A as seen in 10,000 operational tests. The average current chop is actually 0.55A, which leads the industry creating the lowest switching transients and prolonging the life of costly motors and transformers.

Joslyn Clark designs vacuum contactors to provide low switching transients, prolonging the life of inductive loads such as motors, transformers, and shunt reactors. Joslyn Clark’s proven proprietary contact material offers an optimal combination of low switching transient, contact weld resistance, resistance to erosion, current carrying capacity, and interrupt rating.