When specifying a vacuum contactor, you will need to decide between an electrically held (non-latching) vacuum contactor or a mechanically latched vacuum contactor. It is essential to know the difference between electrical and mechanically latched vacuum contactors for proper mounting, installation, and performance.

Electrically Latched Vacuum Contactors

Electrically held vacuum contactors require a continuous control power source for the contacts to be closed. If you lose power or have a weak electrical system with sever voltage sag, the contacts could automatically spring open. Due to fewer components, electrically held contactors have a smaller footprint.

Mechanically Latched Vacuum Contactors

Mechanically latched vacuum contactors do not require a continuous control power source. A short control power signal is needed to close a contact and become latched. If a mechanically latched vacuum contactor loses control signal, the contacts will stay closed. A separate, short power signal is required to release mechanically latched contacts. This type of contact mechanism will take up slightly more space in the cabinet due to the extra components needed.

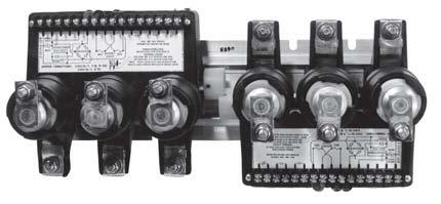

Mechanically Interlocked Reverser

To get the most out of your vacuum contactor, you should also consider whether your application requires a mechanically interlocked reverser. Applications that require forward and reverse motion from the motor will most likely need a mechanically interlocked reverser. The mechanically interlocked option offers one contactor dedicated to the forward motion while another is dedicated to reverse direction. You can implement this option by a mechanical “latch” or lever that prevents both contactors from closing at the same time. In this type of application, proper motor function depends on only one contactor operating at a time.

How to specify vacuum contactors for high altitude environments

What are switching transients and how to minimize them with vacuum contactors

CV Series Compact Vacuum Contactor

Joslyn Clark’s Compact CV Series Vacuum Contactors and Starters are ideal for tough industrial applications. The compact design provides flexibility for retrofitting air break contactors, thus enabling an existing application to continue with maintenance cost and down time eliminated. Voltage raging from 600V to 1500KV and current ratings up to 600A are available.Learn more »

MVC Series Medium Voltage Vacuum Contactor

The Joslyn Clark USAVAC medium voltage vacuum contactors are 3-phase motor contactors built for control and protection in medium voltage applications ranging from 2300V to 7200V. Current ratings of 200-1200 ampere, and motor ratings up to 7000 HP at 6600V are available.Learn more »