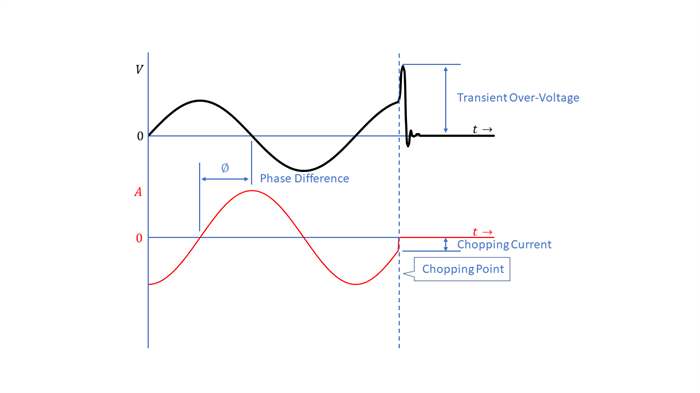

In a typical switching operation, such as a contactor or breaker opening or closing, switching transients occur on an electrical load each time an abrupt circuit change, or current chop, occurs. Inductive loads are most sensitive to such abrupt circuit changes. Below, Figure 1 illustrates that the current lags the voltage in an inductive load. The most severe transient over-voltage condition is observed prior to the current zero-crossing.

Figure 1. As the current decreases, the voltage is actually increasing towards its peak. Coupling the induced transient voltage on top of the system line voltage, this scenario presents the highest voltage across the contact gap, therefore increasing the odds of stresses within the inductive load.

Current chop before current zero causes voltage spikes (known as switching transients) can damage loads like electric motors or dry type transformers. Over-voltages from switching transients may result in insulation degradation. Over time, this can lead to flashovers or insulation breakdown. Flashovers can trip protective devices and force equipment to be out of service. Eventually, insulation breakdowns leads to permanent equipment damage. A vacuum contactor’s low switching transient prolongs the life of inductive loads by minimizing chop current which, in turn, minimizes switching transients.

How Can You Minimize Switching Transients with Vacuum Contactors?

To minimize switching transients, or reduce transient over-voltages, the arc in the vacuum interrupter must maintain current flow to the load as close to the next current zero crossing as possible while the contacts are opening. The dielectric strength between the opening contacts must also increase to a point where it is strong enough to prevent a restrike after current chop.

The selection of contact material impacts switching transient voltages. Below, Figure 2 compares the chop current level of three commonly used contact materials in vacuum interrupters. The proprietary WCAg contact material in Joslyn Clark Vacuum Contactors leads the industry with the lowest chop current level, therefore creating the lowest switching transient.

Figure 2. Comparison of chop current level across different contact materials used within vacuum interrupters.